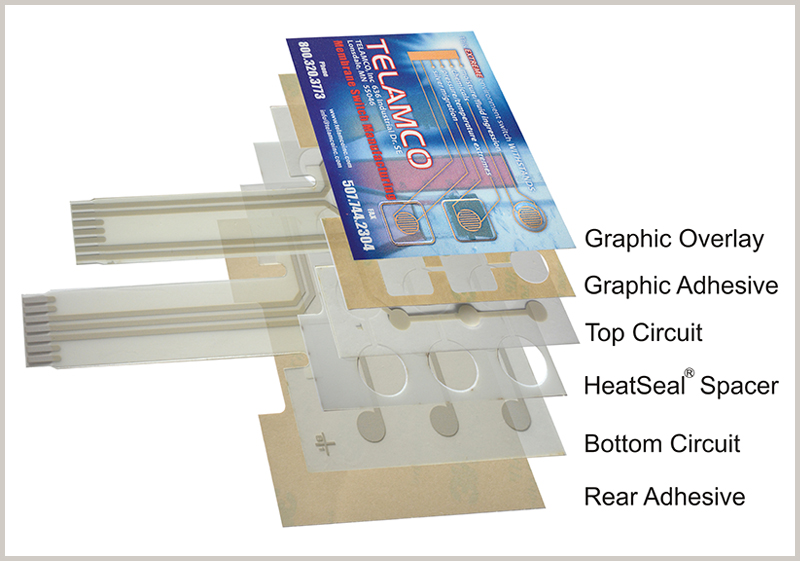

Telamco Membrane Switches with HeatSeal® Technology are Designed to Last

Applying HeatSeal® technology to our high quality electronic membrane switches allows them to operate in environments where pressure sensitive adhesive (PSA) switches often fail.

How HeatSeal® is Different

The materials and processes used in the fabrication of HeatSeal® produces a true hermetically-sealed tactile switch/keypad. The adhesive bond produced in the HeatSeal® process is superior to that of PSA construction found in other electronic switches. The bond effectively seals out harmful environmental contaminants that can cause failure in standard PSA switches. Because air neither enters nor escapes a HeatSeal® switch, external venting is not required even when subjected to changes in temperature or atmospheric pressure.

- Completely Sealed Switch

- High Chemical Resistivity

- Extraordinary Bond Strength

- Superior ESD Protection

Tested to the Extreme

- Gasoline Immersion – HeatSeal® spacer immersed in gasoline for 14 days with no visual signs of degradation.

- General Purpose Cleaners – HeatSeal® spacer soaked in four common household cleaners with no effect. PSA switch damaged within as little as 20 days.

HeatSeal® protects against contaminants by automatically incorporating safeguards in the design, producing the highest-quality membrane switches in the marketplace.

100% Tested – Every product is tested and guaranteed for quality and workmanship. Ensuring tight tolerances and specifications.

Made in the USA – Manufactured in Lonsdale, MN.

Request a Quote

Let Us Help

Do you need an environmentally sealed membrane switch that is made to survive?

Submit a brief description of your project.

We’ll help you find a solution!