Telamco offers various circuit options for your product requirements

Incorporating HeatSeal® technology with any of these options, your membrane switch will endure extreme and benign environments.

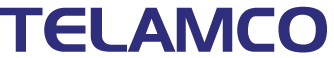

Screened Silver

The most common and cost effective circuit for a custom membrane switch is screen printed silver conductive ink on a heat stabilized polyester substrate. Telamco can also eliminate or reduce silver migration by incorporating HeatSeal® technology with screened silver circuitry.

Screened Silver benefits:

- Lowest Cost Option

- Thin design

- Most commonly used

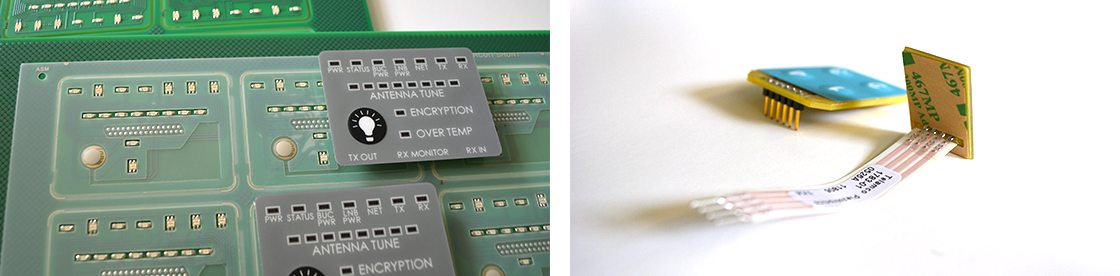

Flexible Printed Circuits

Telamco can use flexible copper circuits which provide more robust design options when space is limited and circuit density is increased. By incorporating HeatSeal® technology with flex copper circuits we can combine surface mount components into a harsh environment flexible copper circuit assembly.

Flexible Printed Circuits benefits:

- High circuit density

- Single or dual sided

- Thin and flexible

- Extremely durable

- Can solder electronic components like LEDs directly on circuit

- Higher current voltage capability

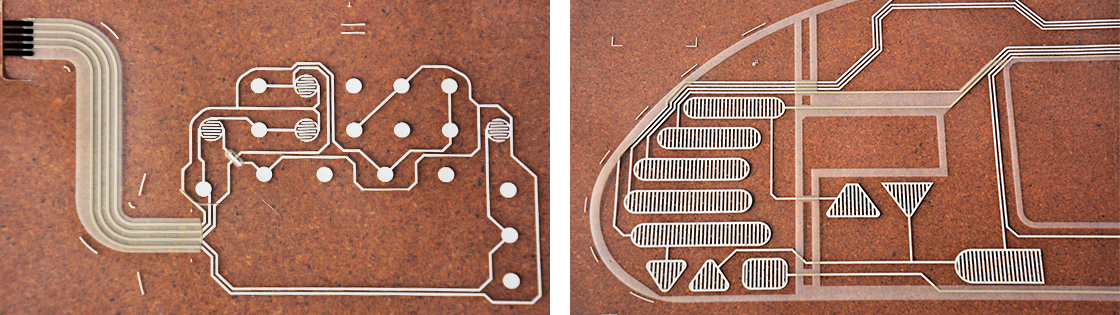

Printed Circuit Boards (PCB)

Printed circuit boards can allow you to combine your user interface and controller electronics into one assembly simplifying design, reducing space and potentially lowering the total cost of your product.

Printed Circuit Boards benefits:

- High circuit density

- Multi-circuit layers

- Simplify design

- Reduce space

- Rigid

- Can solder electronic components

- Potential cost savings

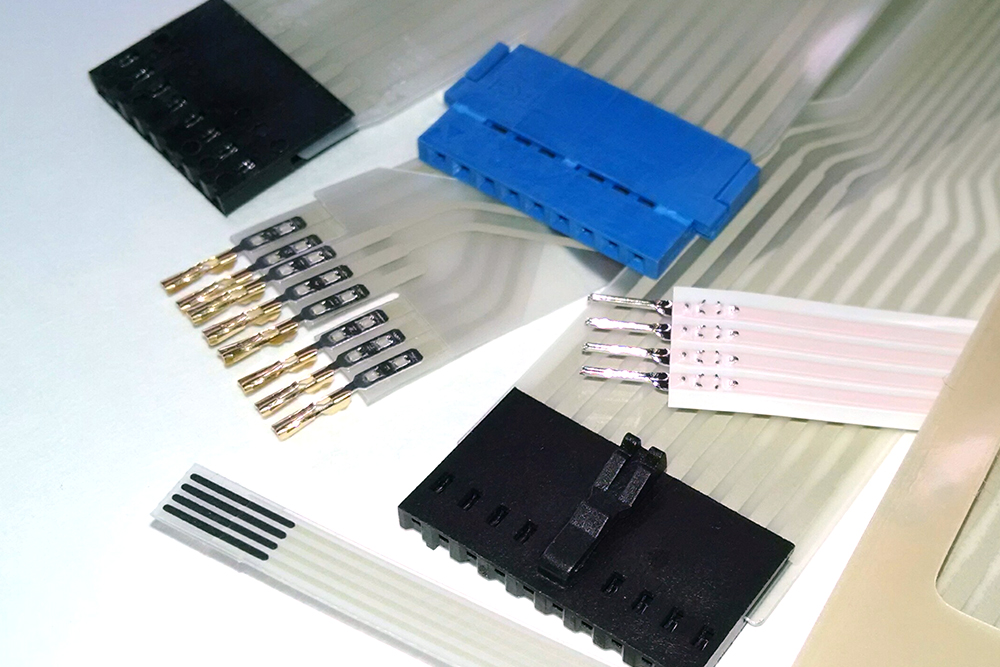

Connectors

Telamco provides switch connectors to meet your requirements and to allow for smooth communication with your end product. Dependent on customer’s needs, we have a variety of connecting options, such as printed traces-ZIF, male/female connectors-latching and polarized and solder tabs.

Telamco provides switch connectors to meet your requirements and to allow for smooth communication with your end product. Dependent on customer’s needs, we have a variety of connecting options, such as printed traces-ZIF, male/female connectors-latching and polarized and solder tabs.