Environmentally Sealed Membrane Switches Made to Survive

Incorporating Telamco’s composite switch into the design of your printed circuit board will provide cost savings, space savings, mounting and functional considerations. Applying HeatSeal® technology to our high-quality membrane switch manufacturing allows them to operate in environments where pressure sensitive adhesive (PSA) switches often fail. Plus, every part is 100% tested to ensure quality you can trust.

Membrane Switches Designed to Last

At the design stage, not every environmental condition under which the membrane switch will operate is known. A common spilled beverage in an office environment can disable a PSA switch, but HeatSeal® protects from contaminants like this. HeatSeal® automatically incorporates safeguards in the design.

Telamco’s exclusive affiliation with The Bergquist Company enables us to offer HeatSeal® technology to low and mid-volume membrane switch users. HeatSeal® is a registered trademark of The Bergquist Company.

Telamco proudly manufactures custom membrane switches that can be found in products in many industries.

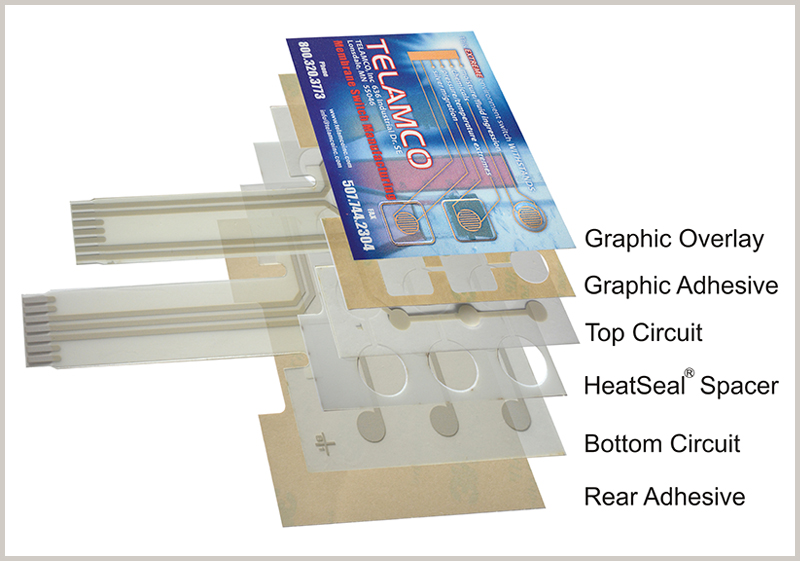

There are many associated components in addition such as overlays, circuits, connectors, lighting and back panels that we manufacture and apply to membrane switch products.

HeatSeal® Technology

The thermal processes used in the fabrication of HeatSeal® switches use heat and pressures to produce a true hermetic seal. The adhesive bond produced in the HeatSeal® process is superior to that of PSA construction found in other custom membrane switches. The HeatSeal® bond effectively seals out harmful environmental contaminants that can cause failure in standard PSA switches.

Because air neither enters nor escapes a HeatSeal® switch external venting is not required even when subjected to changes in temperature or atmospheric pressure.

Not sure where to start?

Telamco has switch engineering experience to assist your staff.

Contact Us Today